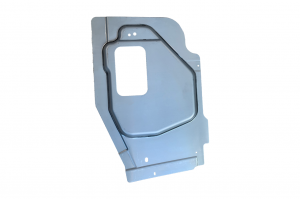

Exterior Rear Floor Pan To Quarter Panel Part

Part Name:

Exterior Rear Floor Pan To Quarter Panel RH/LH

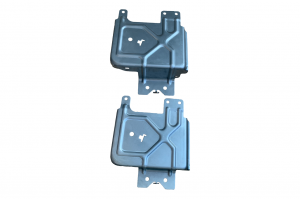

Material Grade: RC5754

Material Size: 2.50mm x 930mm x 690mm

Stage Process: x4 Stage 1500T TRF

Cavity: R and L parts out

Press Machine: 1200T Mechanical, 2000T press

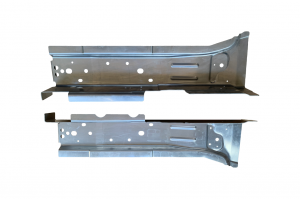

Inspection Tool: Checking fixture, Laser scan, CMM

Lead Time: 6 months

Technical Key Point: High requirement of part flatness and emboss spring back issue

Background:

This part has no bending or flanging, but has a large draw emboss. The flatness of the whole surface is required higher and the tolerance is very small. The poor flatness is caused by surface deformation and wrinkle. Consider of this issue, our designer added a restrike

stage to the process when designed the process layout. Therefore, through the restrike

stage to improve the part flatness, finally part quality shown a good result. Besides, before the part stamping, first after leveling, and then stamping. Not only high precision feeding, but also flatness will be better. When there is a certain flatness requirement in the design of stamping parts, the elastic supporting block can improve the surface flatness of stamping parts.

As to the big emboss, when drawing, there will be a certain amount of spring back, through early forming simulation and make spring back compensation can improve spring back issue.

At the same time, around material flow inside, At the same time, when the surrounding material is flowed inside, the surrounding pressing force should be moderate, and the material flow should be gentle. If the force is too small, the edge will easily wrinkle so that the shape of the emboss is not stamped in place, and it is easy to split if the force is too big. Therefore, the force should be controlled appropriately.

Conclusion:

For the aluminum part and larger part, we have much experience to solve part quality issues when occurred in die tuning and actual production. Our designers are good at early time simulation analysis for avoiding any potential risks of the part quality, which can save the die tuning time and get good quality part.